Circular EconomyAsset Remanufacturing

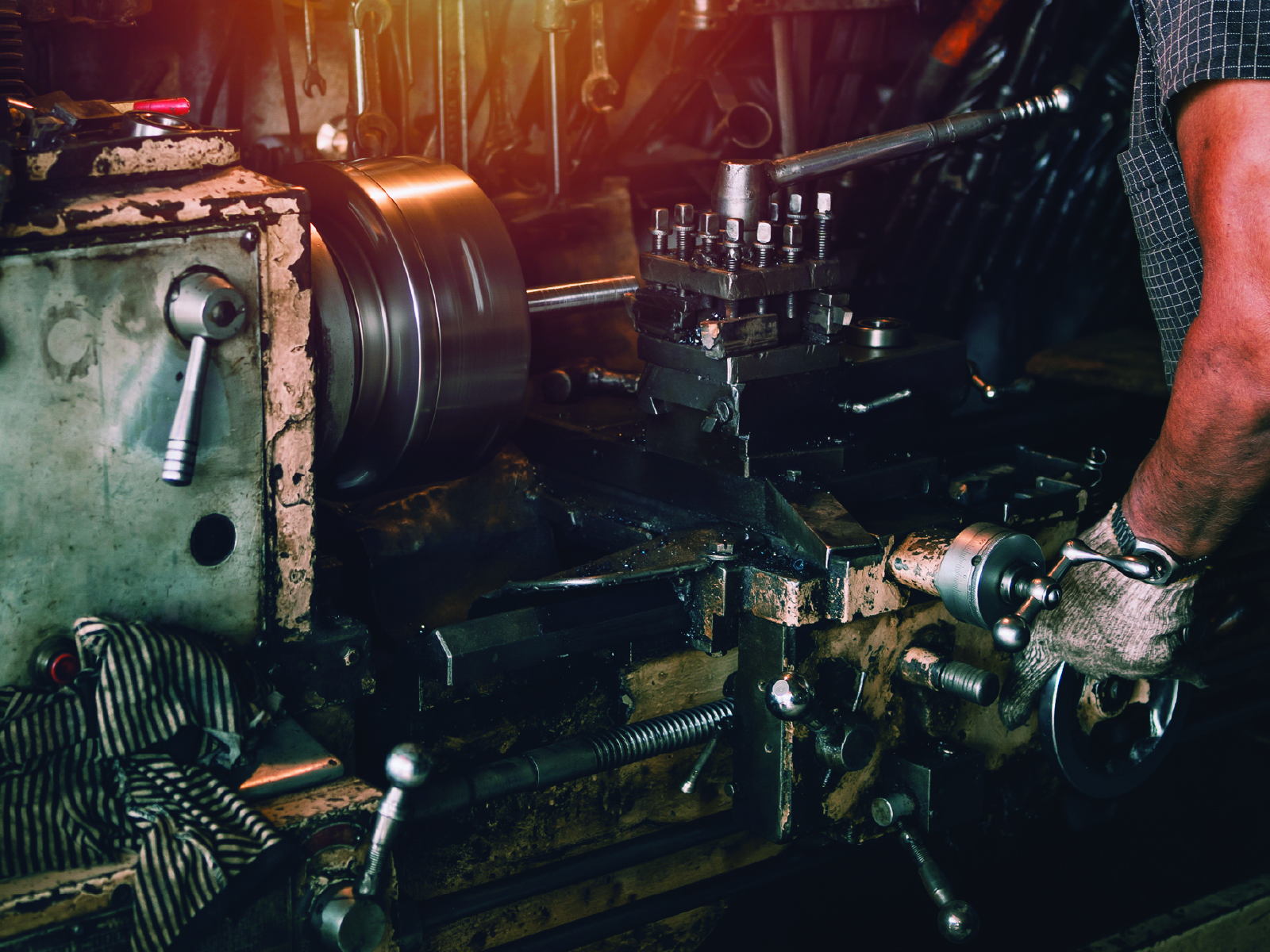

Repair. Refurbish. Remanufacture. Reuse. Recycle.

Repair. Refurbish. Remanufacture. Reuse. Recycle.

Repair. Refurbish. Remanufacture. Reuse. Recycle.

Our planet's resources are finite. A circular economy is a must.

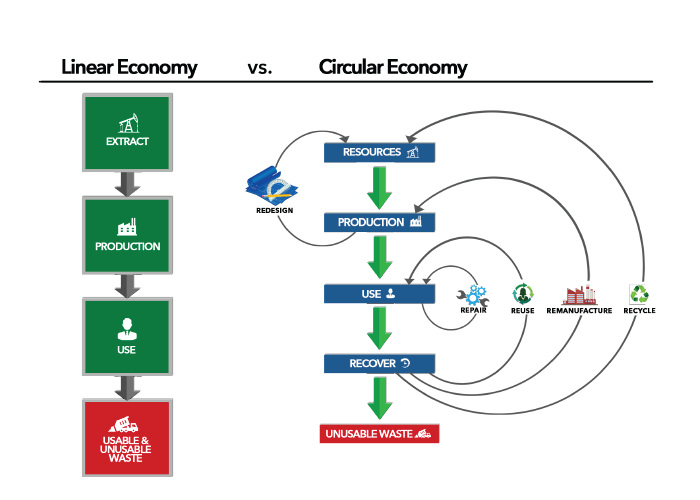

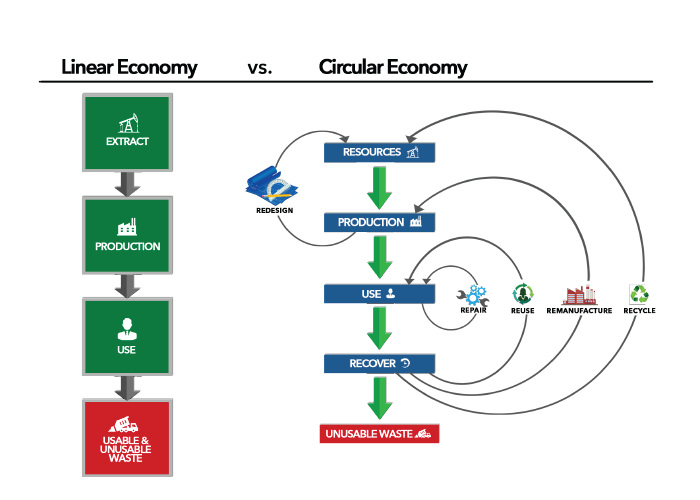

Increasing demand, finite resources, unsustainable practices, and environmental impacts is leading to the outpacing of the world’s use of raw materials. In a linear economy, products are designed and manufactured for single-use, with little consideration for their end-of-life disposal.

Linear vs. Circular Economy

In a circular economy, products are designed to be reused, repaired, remanufactured, or recycled, rather than disposed of as waste.

This promotes resource efficiency, reduces waste and emissions, and creates economic opportunities by keeping materials in use for as long as possible.

What are the 5 "Rs" ?

Repair

Repair returns a faulty or broken product or component back to a usable state.

Reuse

Reuse and repurposing entails utilizing or reselling the product for the same or a different application.

Refurbishment

Refurbishment improves a product through cosmetic fixes and limited upgrades to functionality.

Remanufacturing

Remanufacturing restores a used product or a component to as-good-as-when-new or better condition by way of a standardized process in an industrial setting.

Recycling

Recycling is the recovery of materials and energy contained in end-of-life products.

What is Remanufacturing?

Remanufacturing is the industrial process of returning end-of-service life or aged but valuable assets to same-as-when-new or better condition in a manufacturing environment. This process minimizes the ecological footprint of manufacturing by increasing the useful lifespan of assets and reducing waste.

Remanufacturing is the only approach that provides a full new life to the asset and can potentially enable multiple service lives. Hitachi R&D is deeply committed to creating innovative solutions that accelerate the transition to a circular economy and protect the planet.

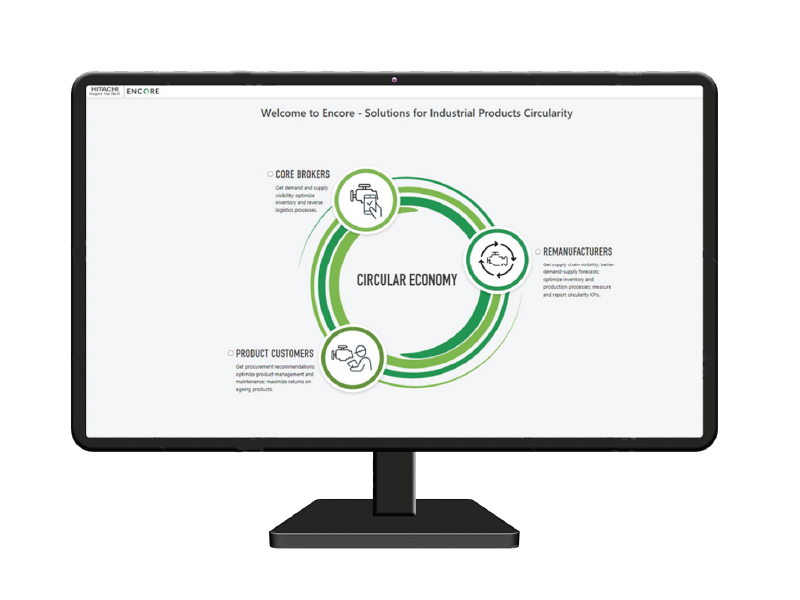

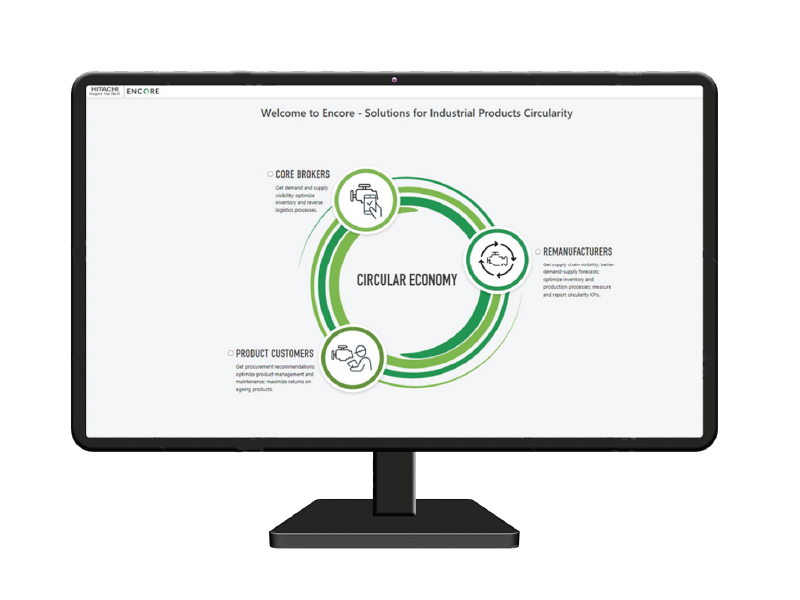

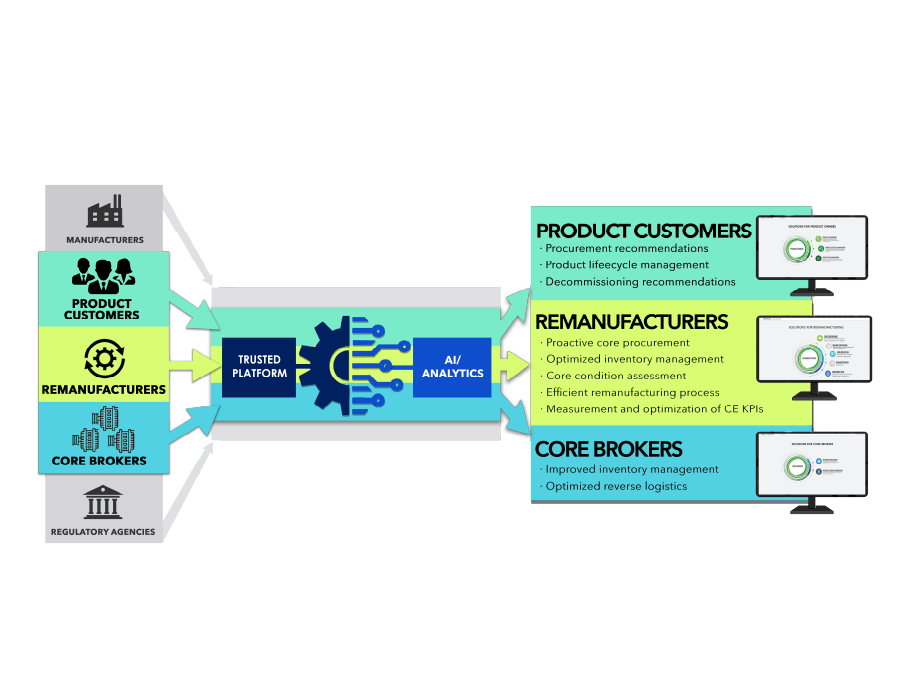

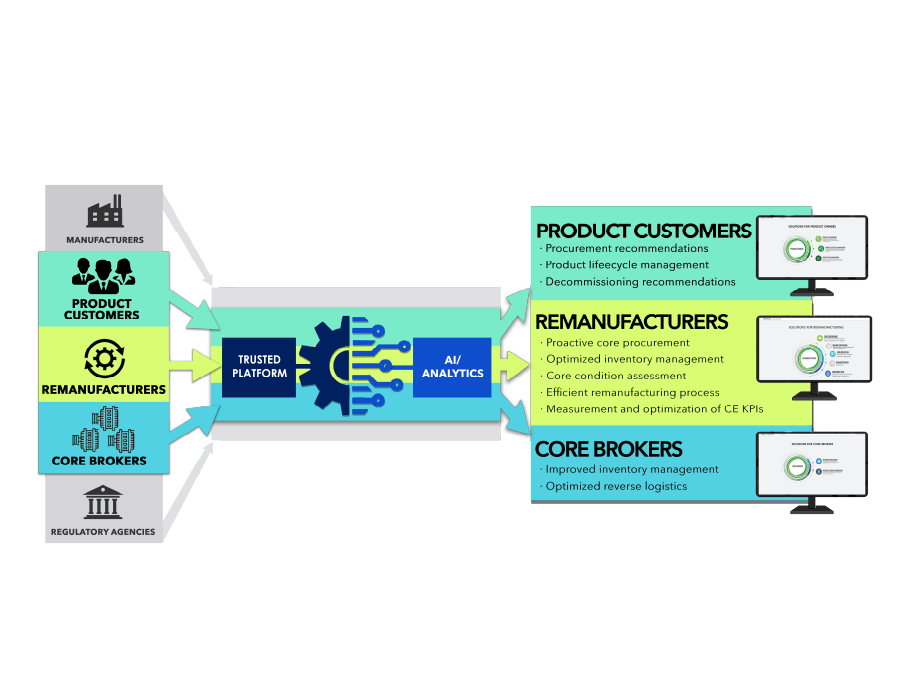

Multiple Stakeholders in a Circular Economy

To achieve circularity, it is essential for multiple stakeholders to collaborate and work towards shared goals. This requires stakeholders to optimize their operations within the broader context of the entire value-chain, rather than solely in their own limited context. To achieve this, stakeholders need improved visibility and access to information from other parts of the value-chain, while also capturing and sharing more information with their counterparts.

Hitachi Encore

Hitachi Encore is a trusted platform and AI/analytics solution for stakeholders in the remanufacturing ecosystem.

The trusted platform:

- Provides a single source of truth for all the value-chain participants throughout a product’s lifecycle

- Enables secure sharing of data between participants and automation of transactions, which reduces friction in transactions

- Built on the principles of big data and addresses the heterogeneity, variety, velocity, volume, and veracity of data

Hitachi Encore

Hitachi Encore is also an AI/Analytics solution:

- Analyzes unified view of the data provided by the trusted platform

- Utilizes advanced machine learning and deep learning methods

- Provides insights and decision support to the participants in the value-chain

Let's Get Started

Discover the possibilities of a circular economy with a strategic partner that possesses in-depth knowledge and extensive experience in remanufacturing and digital technologies to effectively address complex challenges. We foster a strong partner ecosystem and deliver comprehensive solutions tailored to your specific needs.

* Required Field